Kristina Silan

Dual Training & Education + Special Projects Director Dual Training & Education + Special Projects

+63 (2) 8519 8110 kristina.silan@gpcci.org

Biogas technology was first introduced in the Philippines in 1965. However, the technology received little social or economic support at the time. Biogas plants were not yet economically feasible as abundant and cheap coal was primarily used to generate power. In the following decades, practical biogas applications were limited to biogas digesters for home use. Today, there are several industrial-scale biogas plants in the Philippines that generate energy from organic waste.

The Philippines is an agricultural country that has potential to generate large quantities of biowaste and is committed to attaining a sustainable and clean energy future.

In 2016, the Philippines signed the Paris Climate Accord and committed to address climate change by reducing greenhouse gas emissions by 75% and to increase renewable energy sources to 35% by 2030. Since then, the Department of Energy (DOE) is committed to lessen the Philippine’s dependence on fossil fuels.

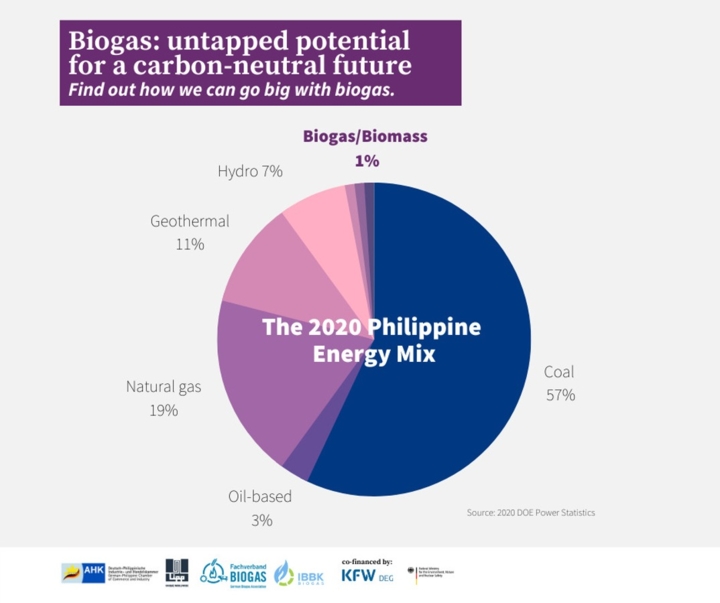

Today, there are several industrial-scale biogas plants in the Philippines that generate energy from organic waste. Despite this development biogas production still plays a rather small role as a renewable energy source. Biogas has accounted for less than 1% of the power generation mix in 2020.

In the Philippines several laws were established to promote waste to energy conversion. Waste-to-energy technology refers to “systems which convert biodegradable material such as but not limited to animal manure or agricultural waste, into useful energy through processes such as: anaerobic digestion, fermentation, and gasification. Section 30 of Republic Act (RA) 9513, which promotes the development of renewable energy, provides for the use of “waste-to-energy” technology subject to requirements of RAs 9003 and 8749.

Promotes the establishment and operation of Waste To Energy facilities which aims to help the economy to reduce reliance on imported oils and increase in power generation.

Provides for the creation of a national program of air pollution management focusing primarily on pollution prevention. Among its provisions are the regular monitoring of greenhouse gases and prohibition of the use of the incineration methods.

Here are 11 informative facts about biogas in the Philippines and the generation process.

As part of the project, Lipp GmbH in association with GPCCI established a research partnership with Mapúa University-Intramuros. Through the partnership, Lipp will provide biogas yield testing equipment to Mapúa to support biogas research efforts into new feedstocks, the organic matter that is fermented to generate biogas. Furthermore, as part of the partnership, Mapúa will strengthen biogas awareness raising through its curriculum integration.

Biogas Fachverband (German Biogas Association)

Scan the QR codes for GBA’s biogas guidelines and journal!

Neben der fachlichen Ausbildung von Biogas-Technikern ist die Bewusstseinsbildung für die Potenziale der Nutzung von Biogastechnologie auf den Philippinen ein weiterer zentraler Punkt des „Pineapples to Power“ Projektes. Hierfür organisierte GPCCI verschiedene Informationskampagnen und entwickelte Wissensprodukte, die auf dieser Webseite kostenlos zur Nutzung bereitstehen.

The “Pineapples to Power” project is an initiative of the German company Lipp GmbH, a maker of biogas tanks and plants, to support the renewable energy transformation in the Philippines by converting bio-waste into energy. The objective of the 3-year project is to train Filipino technicians on the construction, maintenance, and safe handling of German technology biogas plants.

Dual Training & Education + Special Projects Director Dual Training & Education + Special Projects

+63 (2) 8519 8110 kristina.silan@gpcci.org